What is mining?

Mining is one of the activities of mineral exploitation, extracting geological materials from the earth’s interior, which are typically ore, veins, and coal seams. The types of materials extracted from mines include basic metals, precious metals, uranium, coal, diamonds, limestone, oil shale, rock salt, and potassium carbonate. All materials that are not produced by agriculture or in laboratories and factories are extracted from mines.

Mining technology consists of two main groups

- Open-pit mining

- Underground mining

The types of materials are usually divided into two groups: industrial minerals, including valuable minerals found in riverbeds, coastal sands, and other loose materials, and ore veins, which are minerals with value found in veins, layers, or mineral particles scattered throughout rock formations.

Specialized for mining and mineral industry, the following are the types of forklifts

MT/MT-X 625 Forklift

- Lift height: 5.85 m

- Load capacity: 2500 kg

- Maximum reach: 3.40 m

MT-X 733 Forklift

- Lift height: 6.9 m

- Load capacity: 3200 kg

- Reach: 3.90 m

- Travel speed: 27 km/h

MT-X 1033S Forklift

- Lift height: 9.98 m

- Load capacity: 3200 kg

- Maximum reach: 7.15 m

- Travel speed: 27 km/h

MHT-X 790 Forklift

- Lift height: 6.84 m

- Load capacity: 9000 kg

- Dimensions without attachments (L x W x H): 5.27 x 2.47 x 2.48 (m)

- Travel speed: 30 km/h

MHT-X 10180 Forklift

- Lift height: 9.63 m

- Load capacity: 18000 kg

- Dimensions without attachments (L x W x H): 6.65 x 2.52 x 3 (m)

- Travel speed: 25 km/h

MHT-12330 Forklift

- Lift height: 11.90 m

- Load capacity: 33000 kg

- Dimensions without attachments (L x W x H): 8.45 x 2.99 x 3.60 (m)

- Travel speed: 25 km/h

=> See also: Telehandler

Forklifts in the mining industry are an essential focus, as they help ensure safety and improve efficiency in the extraction process. Therefore, these types of forklifts are considered an advanced lifting solution in resource industries.

Do you want to build in the best conditions?

Forklifts are the solution to improving investment benefits, and you need to continuously build your infrastructure in a shorter period of time and regularly in harsh environments.

With accurate handling and positioning of heavy and bulky objects, preparation of land, and without compromising safety.

Safety

Advanced equipment (standard/optional) with stable safety equipment, Cabin Rops/Fops, rear and pedestrian observation cameras, and more types of accessories.

360° panoramic view and comfortable cabin with many features such as customizable machine operation and accessory training, emergency brake, and steering.

Filter and dilute exhaust fumes

Performance

Fast travel speed and cycle time to quickly return on investment or for rental purposes.

Accurate execution is possible with hydraulic machines, proportional control, and specialized remote control accessories such as lifting forks, shovels, cranes, Jib cranes, etc.

Choose the best machine and accessories solution for your needs. Manitou offers forklifts from 3 to 7 tons, straight boom forklifts with heights up to 31.5m, excavators, and many other devices.

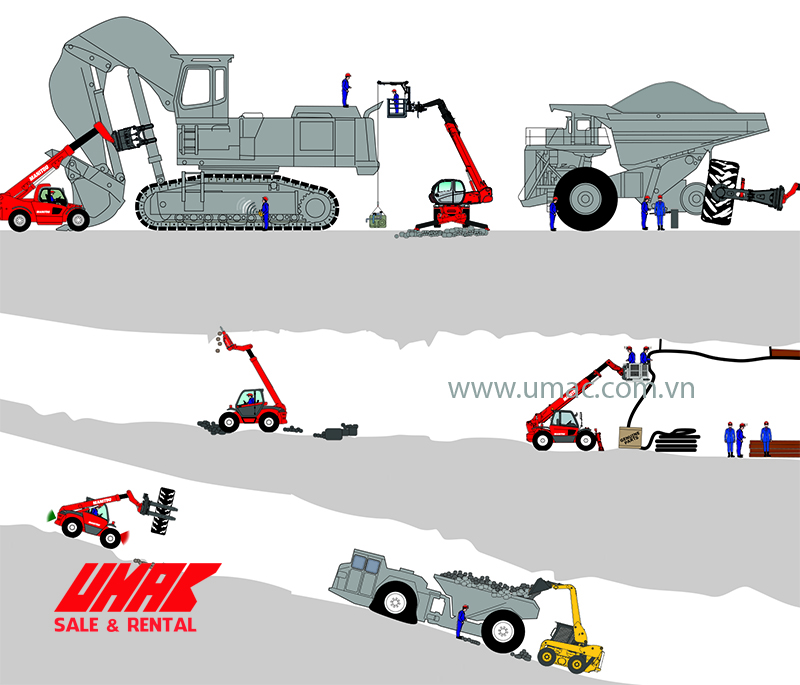

Manitou forklifts meet critical needs in the mining industry

Loading, installing, and safely removing stored materials (crusher parts, cylinders, or tires), stacking and placing them in warehouses are all important operations that support the extraction process.

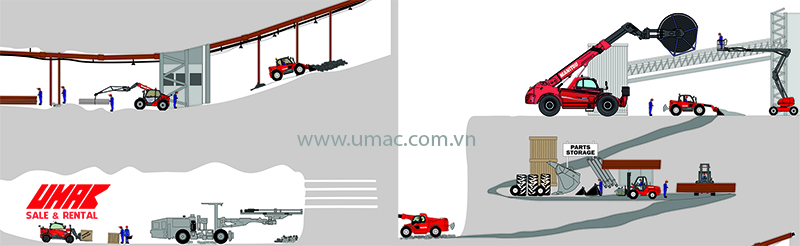

From manual pallet forklifts to electric forklifts through forklifts with loading and order-picking personnel. Manitou’s mining forklifts provide high mobility and stability. Industrial forklifts: perfectly adaptable for both indoor and outdoor operations with excellent terrain capability. Due to their simple design and adaptability to all types of surfaces, they are easy to maintain, use, and convenient. If you want more flexibility, choose quickly interchangeable accessories: lifting forks, Jib, crane hook, tipping, etc.

To optimize operations, it is necessary to use advanced forklifts.

The necessity for your operations: Checking and maintaining ensures the smooth running of your work. Replacement of wheels, cylinders, engines, hydraulic pumps or tracking rollers through daily building maintenance, you need versatile equipment that can be used well in any situation.

Forklifts bring cost-effectiveness:

- Conduct on-site equipment maintenance

- Diversify investment benefits through various accessory solutions

- Optimize the operating time of production equipment

- Improve maintenance team management by reducing the number of machines

- Enhance maintenance flexibility

Effective solutions from 9-ton to 23-ton forklifts: You can use material handling tools on a daily basis for routine activities. These operations include drilling, bolt tightening, drilling and earth excavation, installation of hanging ventilation fans and pipes, and meeting all time requirements for wetness or dirt.

Conditions: This is why you want to rely on equipment processing and avoid wasting time during operation.

Productivity: When it comes to equipment, we should also consider the productivity that the equipment brings, diversify investment benefits through various accessories. Maintenance is uniform and easy with dynamic engine access, system diagnosis,…changing accessories quickly and easily. It is also the advantage of Manitou forklifts, providing the mining industry with many types of machines and equipment that can meet the challenges of daily operations for your work: from versatile forklifts, skid loaders to compact telehandlers.