U-MAC Vietnam shares with our readers 26 safety principles to pay attention to when using lifting equipment in order to avoid risks, as follows:

- All lifting equipment, machinery, and devices are required to meet safety regulations set by the state for registration and quality inspection before being put into use.

- Units using lifting equipment are only allowed to use devices in good technical condition and are not allowed to use lifting equipment and load-bearing parts that have not been inspected and registered for use.

- Qualified operators who have been trained and certified must be arranged to operate the lifting equipment.

- Load riggers and signalers must be professional or trained in another field.

- Lifting equipment operators must have a firm grasp of the technical characteristics and functional effects of the device’s structural components.

- At the same time, they must be well-versed in the safety requirements during use.

- Lifting equipment must only be used according to the device’s designated function, effect, and characteristics as specified by the manufacturing plant.

- Lifting loads with a weight exceeding the lifting device’s load capacity is not allowed.

- The use of lifting equipment with friction clutch or wedge clutch mechanisms to lift and move people, liquid metals, explosives, toxic substances, compressed gas containers, or liquid is prohibited.

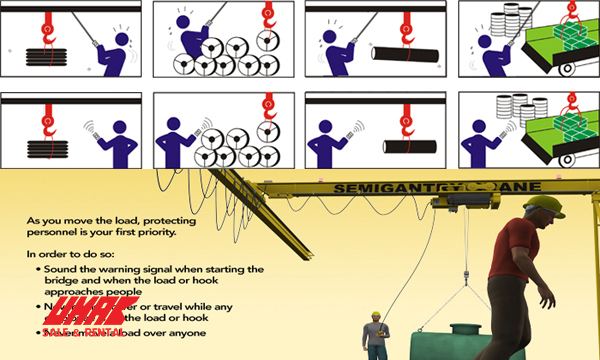

- Lifting equipment can only be used to transfer loads through workshops, homes, or areas with people if there are separate safety measures in place to exclude the possibility of accidents and occupational hazards.

Using 2 or more forklifts to lift a load together is allowed only in special cases and requires a calculated and approved safety solution. The load must be distributed evenly on each lifting device and not exceed its weight capacity. The safety solution must include a load attachment diagram, a load movement diagram, and a clear sequence of operations, as well as requirements for the size, material, and manufacturing technology of auxiliary devices used for load attachment. Experienced personnel will be responsible for directing and overseeing the lifting and transportation process.

During the use of lifting equipment, the following actions are prohibited:

- People climbing up or down while the lifting equipment is in operation

- People within the radius of the crane’s swing

- People in the working area of lifting equipment that uses magnetic, vacuum, or clamp attachments

- Lifting, lowering, or moving the load while someone is standing on it

- Lifting an unstable load or attaching only one side of a double hook

- Lifting loads that are buried under the ground or secured by bolts or concrete with other objects

- Using lifting equipment to lift a load that is being crushed by another object

- Passing the load through a window or balcony when there is no load receiving platform

- Changing the direction of the mechanism’s movement when the mechanism is not completely stopped

- Lifting loads that exceed the corresponding weight capacity for the range and position of the crane’s outrigger

- Carrying or pulling loads with a forklift

- Simultaneously using a person to push or pull the load and operating the lifting and lowering mechanism.

Ensure free access for the crane operator when operating the lifting equipment using buttons from the ground or floor.

When the mobile crane and overhead crane are working, the access to the railway must be fenced.

People are not allowed to be on the bridge and overhead crane when they are in operation. Only cleaning, oiling, and repair work on the bridge and overhead crane can be done with safety measures (preventing falls, electrical shock, etc.).

The unit using the lifting equipment must regulate and organize the signal exchange system between the person hooking the load and the crane operator. The signal used must be specified and cannot be confused with other phenomena around.

When the lifting equipment user cannot see the load during lifting, lowering, and moving, a signalman must be arranged.

Before lifting the approximate load, the load must be lifted to a height not exceeding 300mm, maintaining that height to check the brakes, the strength of the metal structure, and the stability of the crane. If safety is not ensured, the load must be lowered for handling.

When lifting and transferring loads near obstacles, ensure the safety of structures, equipment, and people near them.

Outdoor lifting equipment must stop working when the wind speed is higher than the wind speed allowed by the design of the equipment.

For outdoor lifting equipment, hanging banners, plugs, slogans, or shields to increase wind resistance are not allowed.

The double-track equipment, self-moving prevention equipment of tower cranes, gantry cranes, and pedestal cranes must be tightened when finishing work or when the wind speed exceeds the allowed speed. When there is a storm, additional reinforcement measures must be taken for the above types of cranes.

Allow lowering the load to a designated position where the possibility of falling, tipping, or slipping is excluded. Allow removing the hanging cables of structures and assembly parts from the hook when they have been firmly and stably fixed.

Before lowering the load into the pit, well, etc., lower the empty hook to the lowest position to check the remaining number of cable turns on the drum. Only lift or lower the load when the remaining number of cable turns on the drum is greater than 1.5 turns.

The lifting equipment must stop operating when:

- Detection of excess deformation of metal structures.

- Detection of brake failure in any mechanism.

- Detection of hooks, cables, pulleys, and gears that are corroded beyond allowable limits, cracked or otherwise damaged.

- Detection of damaged or non-compliant railings in lifting equipment.

When loading and unloading goods onto transport vehicles, the stability of the transport vehicle must be ensured. The person securing the load is allowed to approach the load only when the load has been lowered to a height not exceeding 1m from the floor where the load-securing person is standing.

Lifting equipment must be regularly maintained. Parts and components that are worn beyond the allowable limit must be repaired or replaced. When repairing or replacing parts or components of lifting equipment, safety measures must be taken. After replacing or repairing important parts or components such as metal structures, hooks, cables, brakes, etc., a load test of the lifting equipment must be conducted before putting it into use.

For lifting equipment, including cranes and other lifting devices used in construction sites, it is essential to understand the safety principles in order to minimize risks, which has always been a practice in our company.